Home

The tutorial to fight Corona by yourself making your own deactivator at home !!!

Since research institutions and manufactures are halted because of the lock down and fear. It is time for you to take action to protect yourself !!!

This is an open source concept and anyone is welcome to try!!!

There are some classical questions people always ask about this concept:

1. Compare to what?

- Face mask

The face masks don’t filter out the particle size of the virus. Viruses are tremendously tiny, and standard fabric is not going to filter out the virus.

- Social distancing

Stay 6 Feet Apart, We are Told. But How Far Can Air Carry Coronavirus?

- UV Light

UV Light and Health Effects

Potential Risks Associated with Using Ozone Gas or Ultraviolet (UV)

2. What evidence you have?

- Laser destroys bacteria and viruses without using harmful UV radiation

- Biological effects and medical applications of infrared radiation

- In experiment

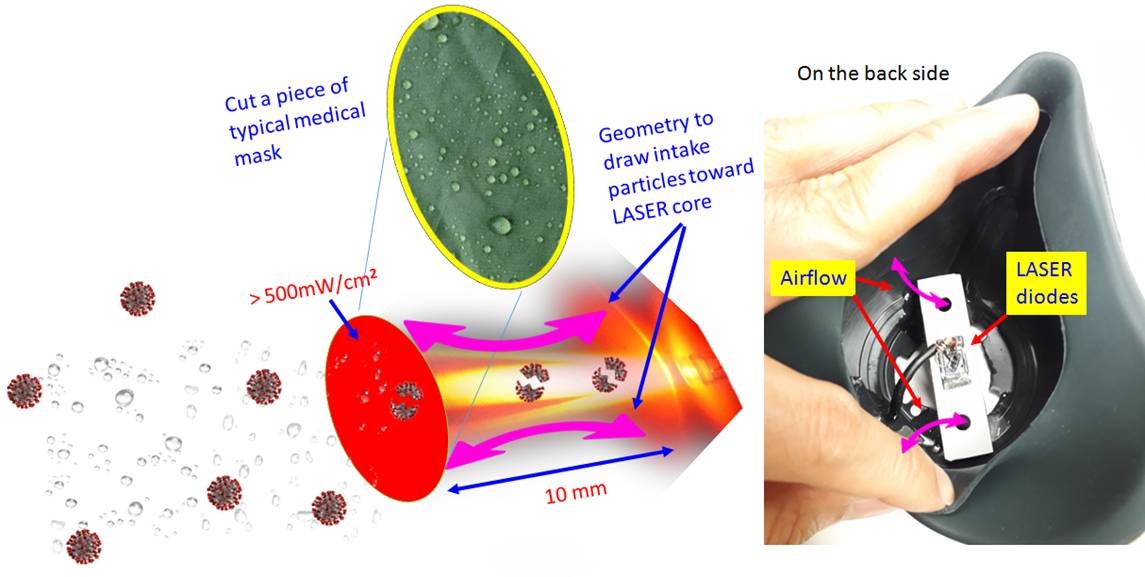

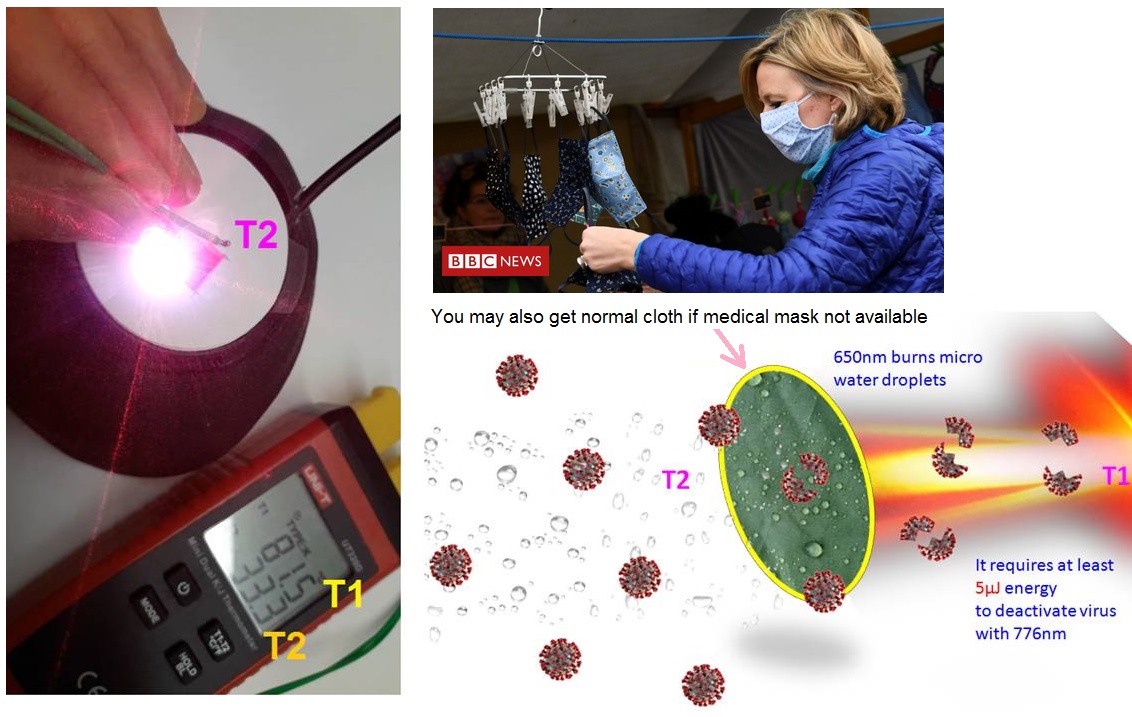

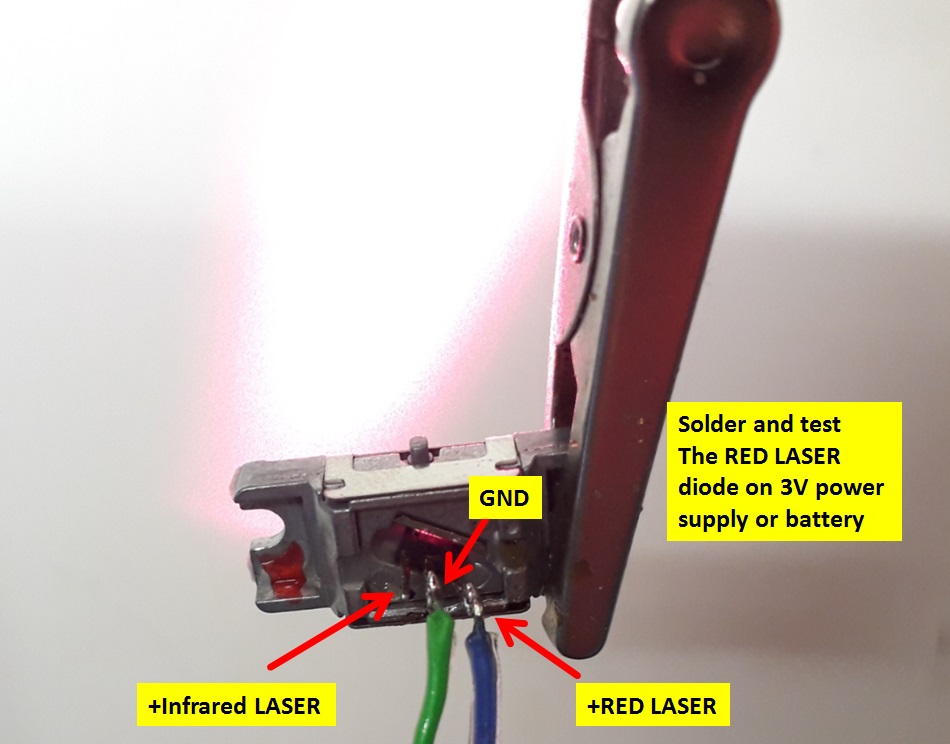

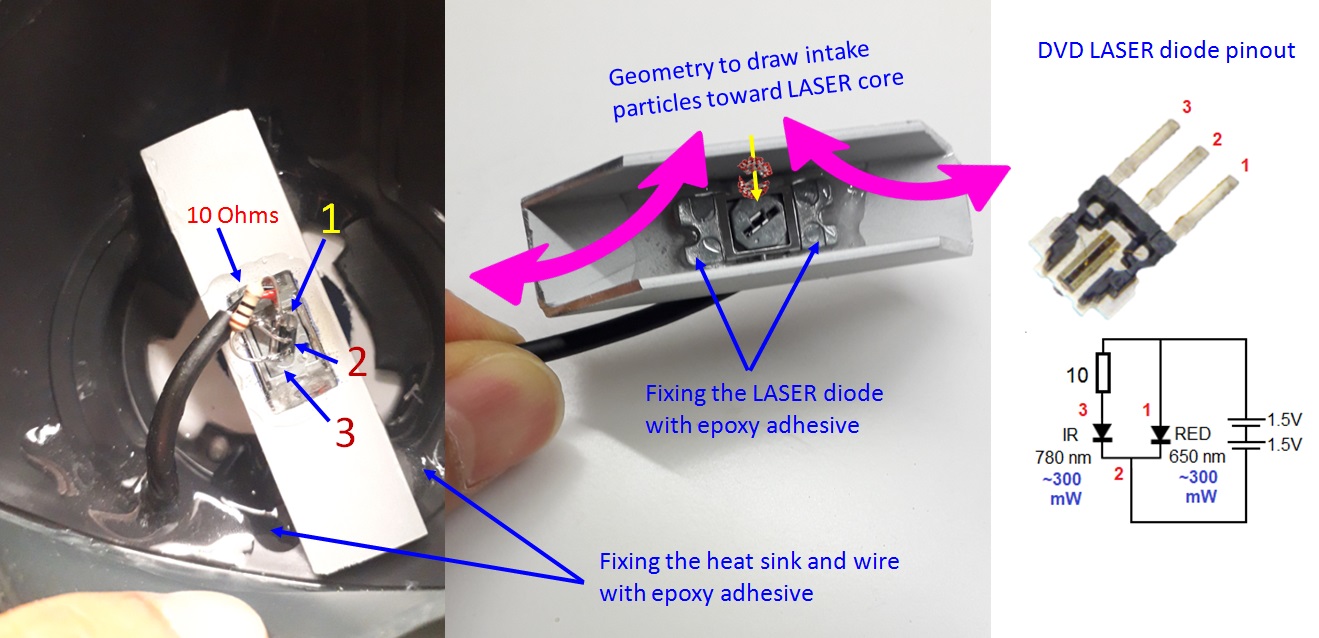

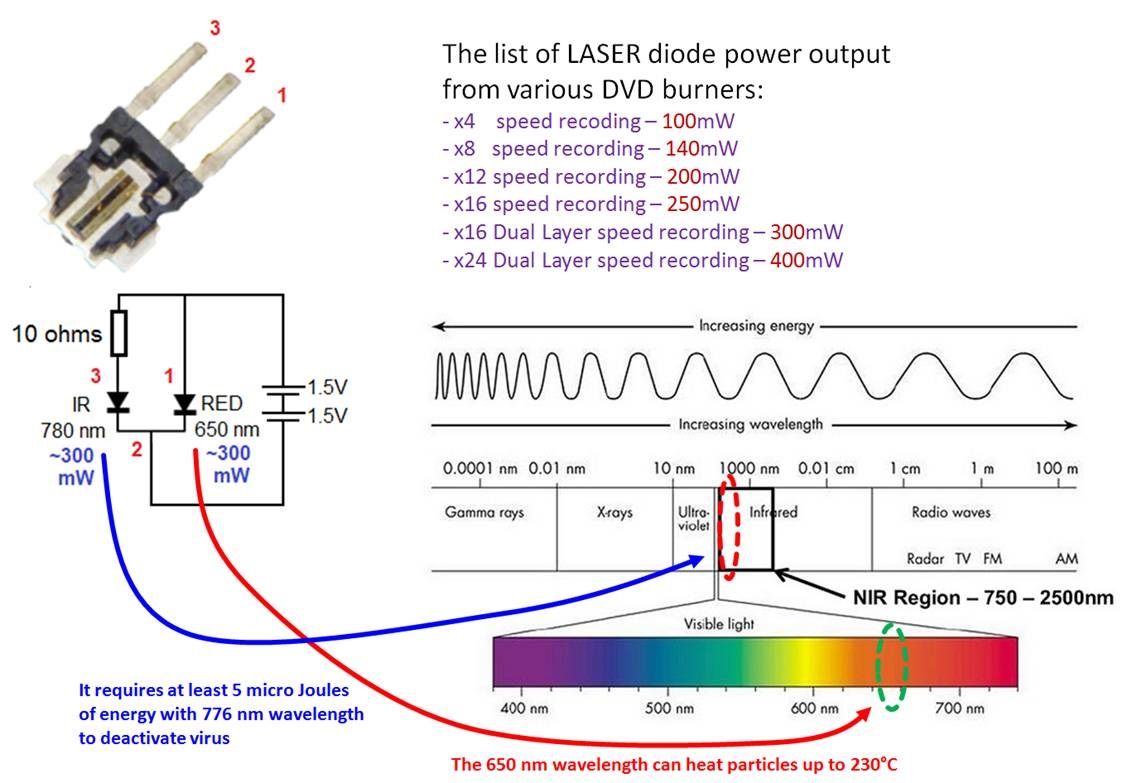

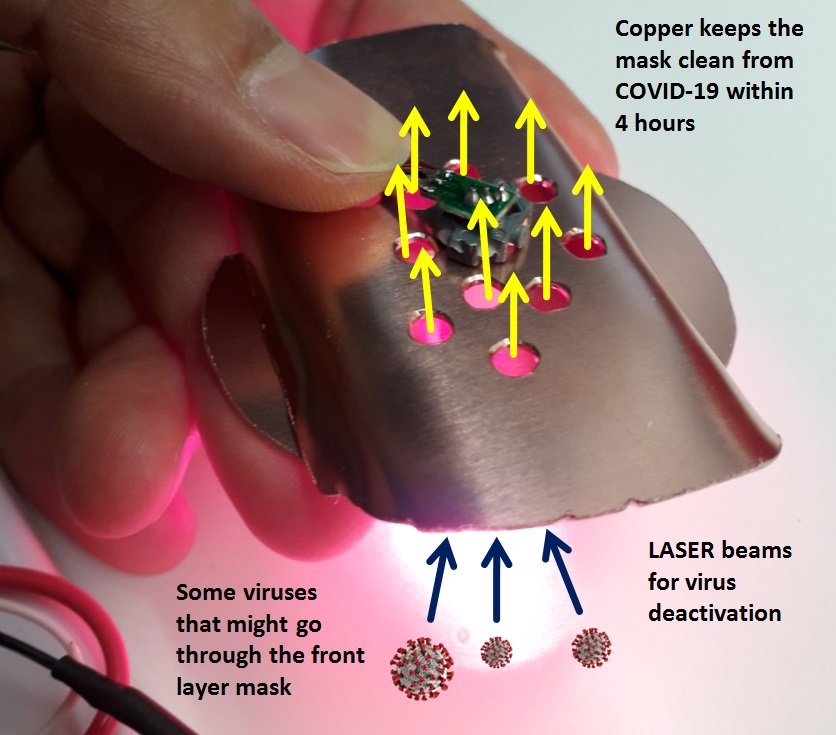

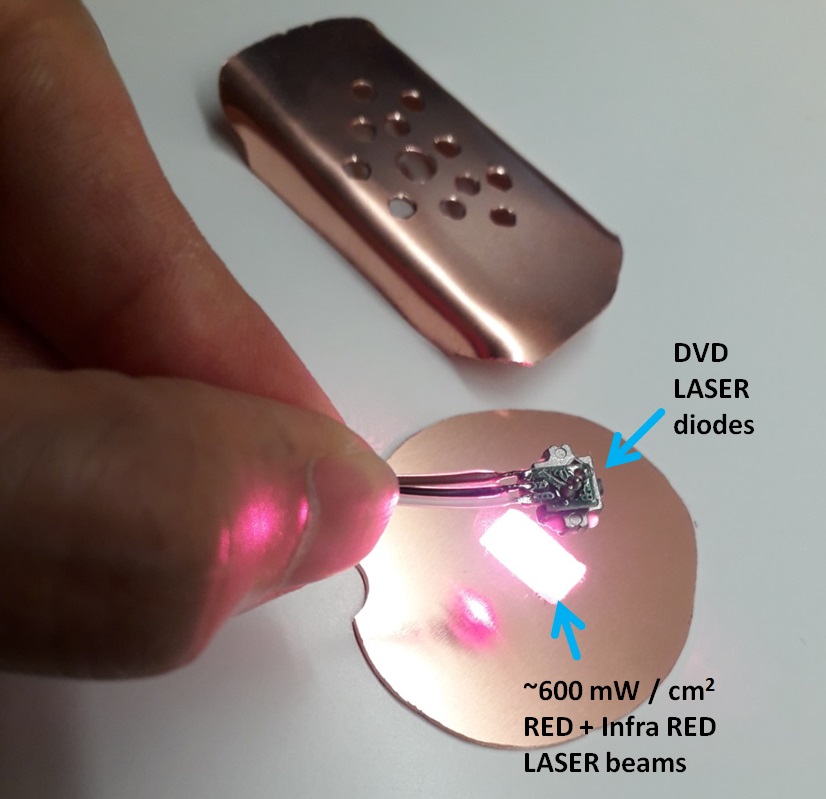

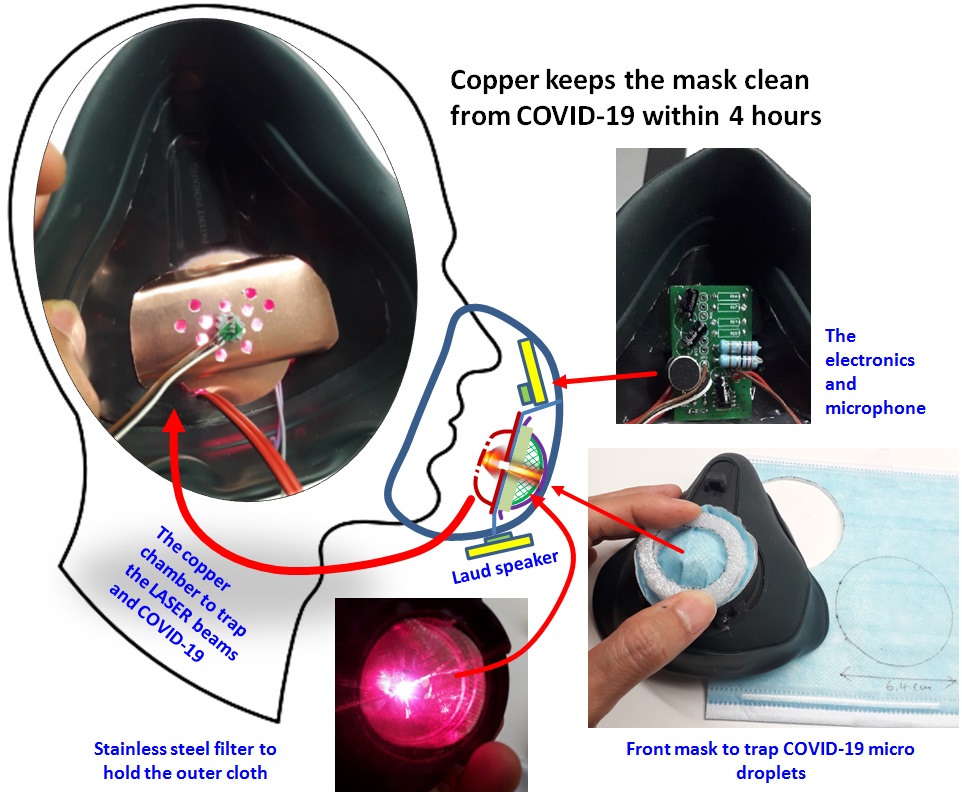

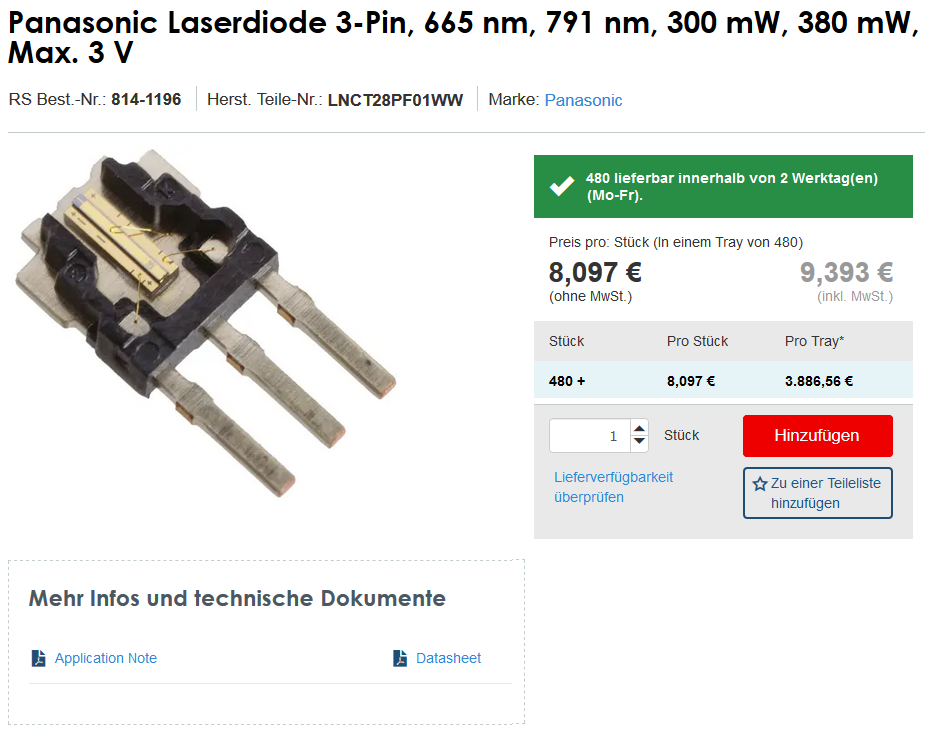

Instead of pulsing the LASER beam, we were experimenting with Infrared and Red LASER diodes simultaneously to burn any object in the air. For the mask, we are shooting the cloth directly with 600 mW/cm2 LASER beams to burn any viruses that manage to penetrate the cloth as we breath in. Since the temperature absorb by the virus particles directly in front of the LASER diodes can easily exceed 100C, the probability for the virus to survive is relatively small.

3. At what cost?

If you are in developing countries and you do not have access to 3D printer or any means to get a plastic mask online, you might make your own wooden mask with simple tools.

If you have access to 3D printer, you might print the plastic mask by getting the open source design from David Sher on 3D Printing Media Network:

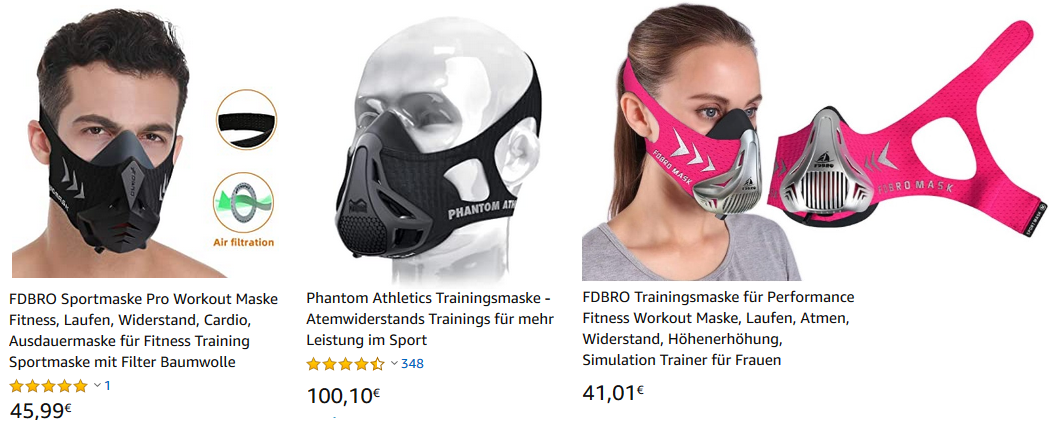

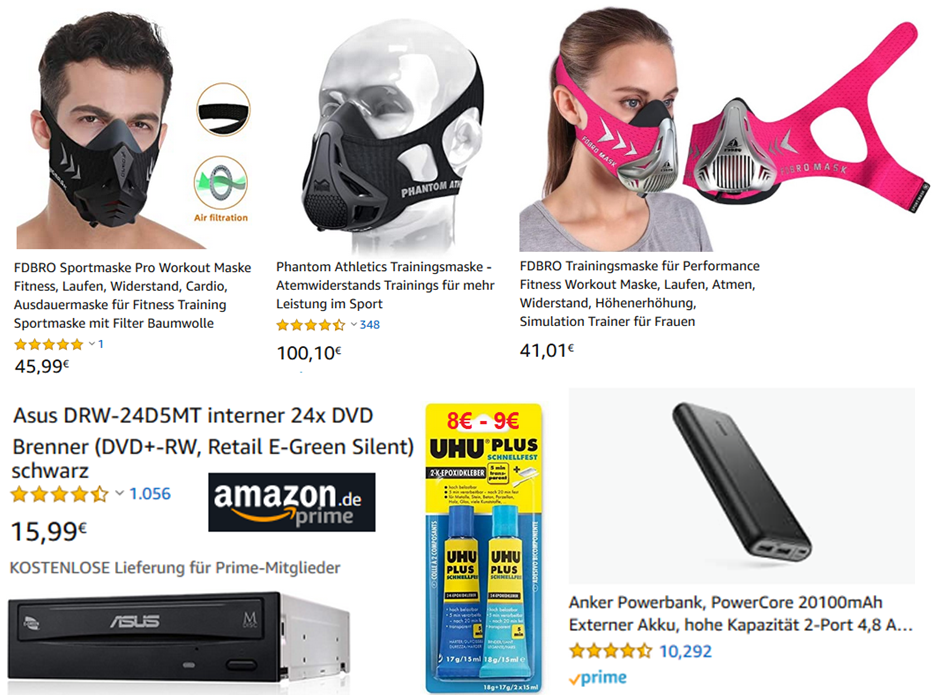

If you have access to online shop, you might get the training mask for modification:

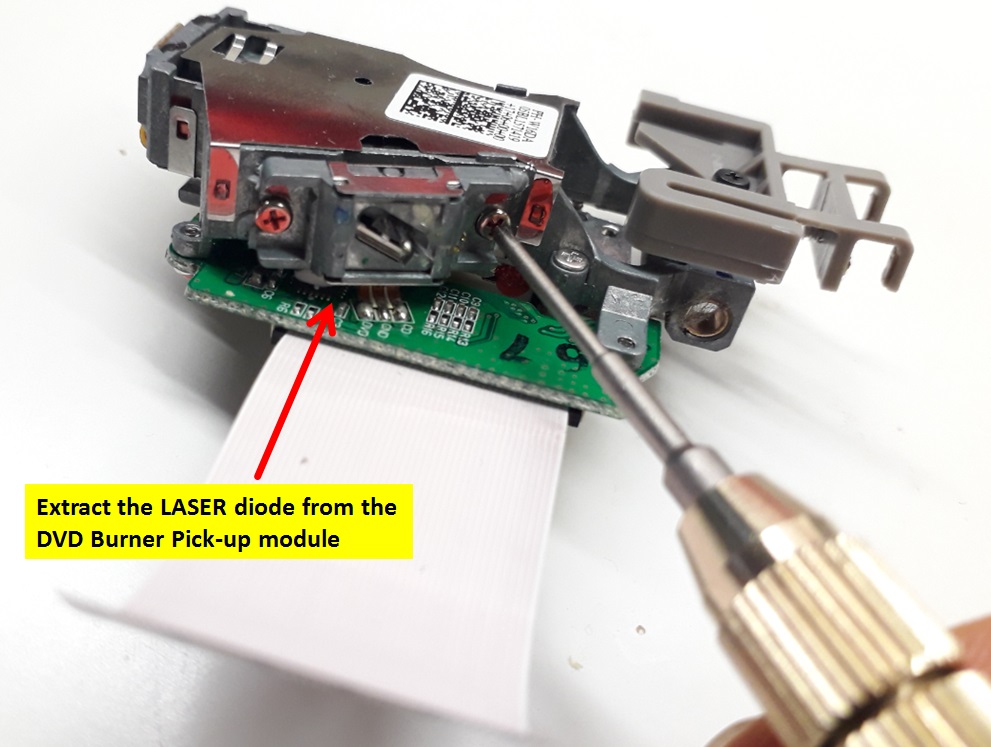

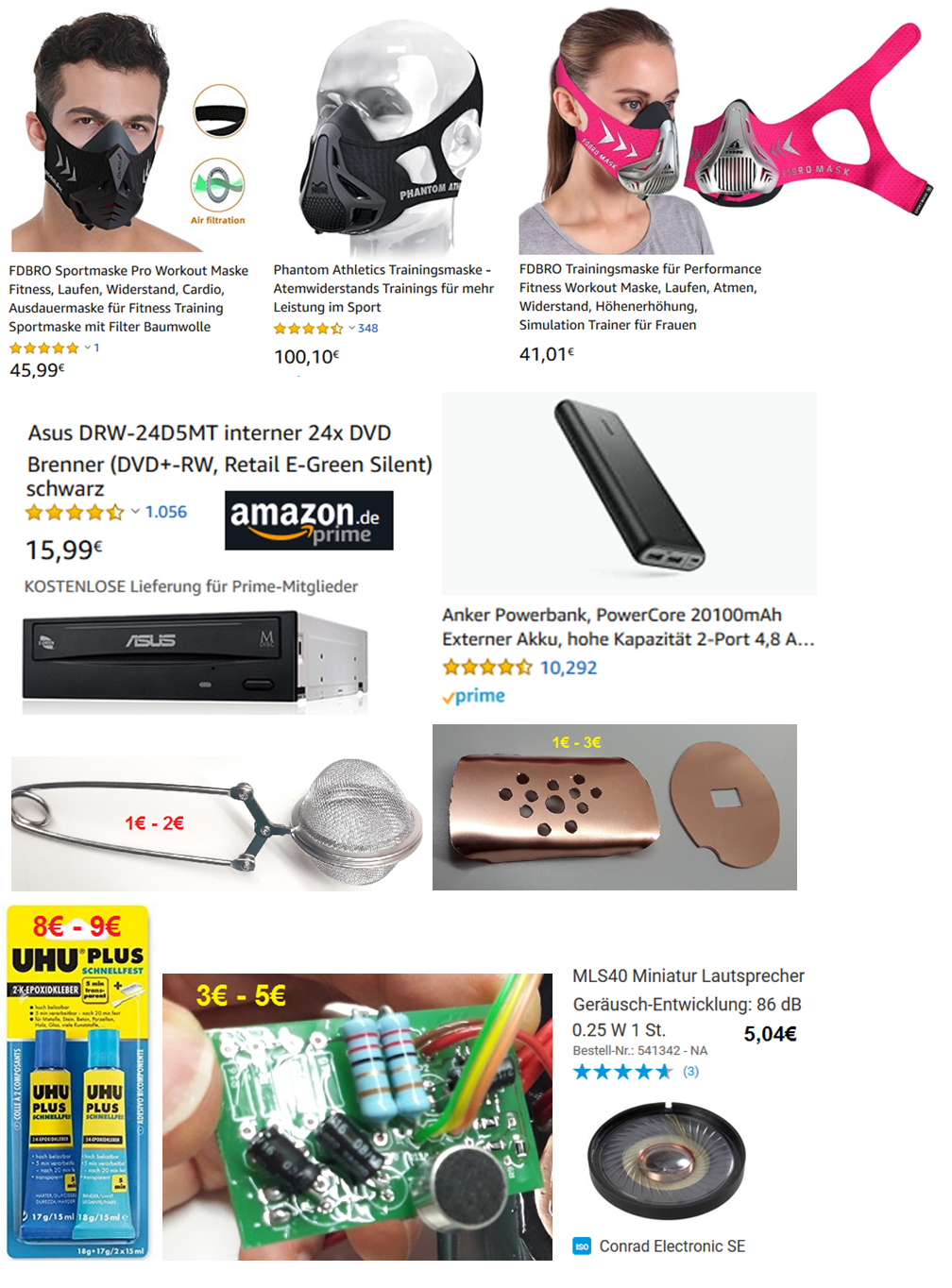

9€ -15€ - DVD Burner at least 16x to 24x write speed

+ ????€ your valuable time to check our YouTube channel and watch the tutorials

Working Principles

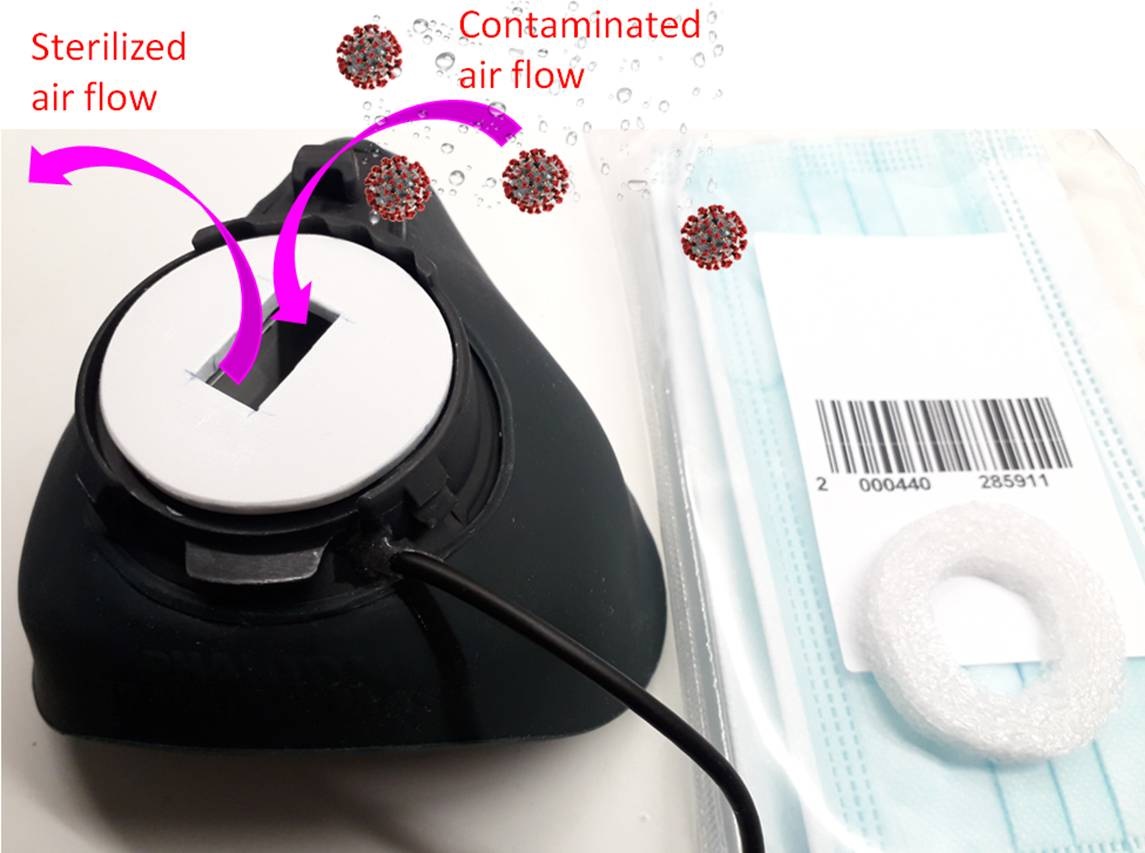

Reusable home made mask report: https://www.bbc.com/news/world-europe-52439926

Measuring core LASER temperature and air temperature. The air temperature from our body was ~34 C when we breath out. The size of Corona Virus is about 80-120 nm. The virus has extremely low mass, hence the heat capacity is very low. The energy of the photons absorbed by the virus molecules shall increase rapidly towards the LASER beams.

it requires very low energy to deactivate the virus (around 5 micro Joules) with 776 nm LASER beam [1].

How to get the LASER diodes

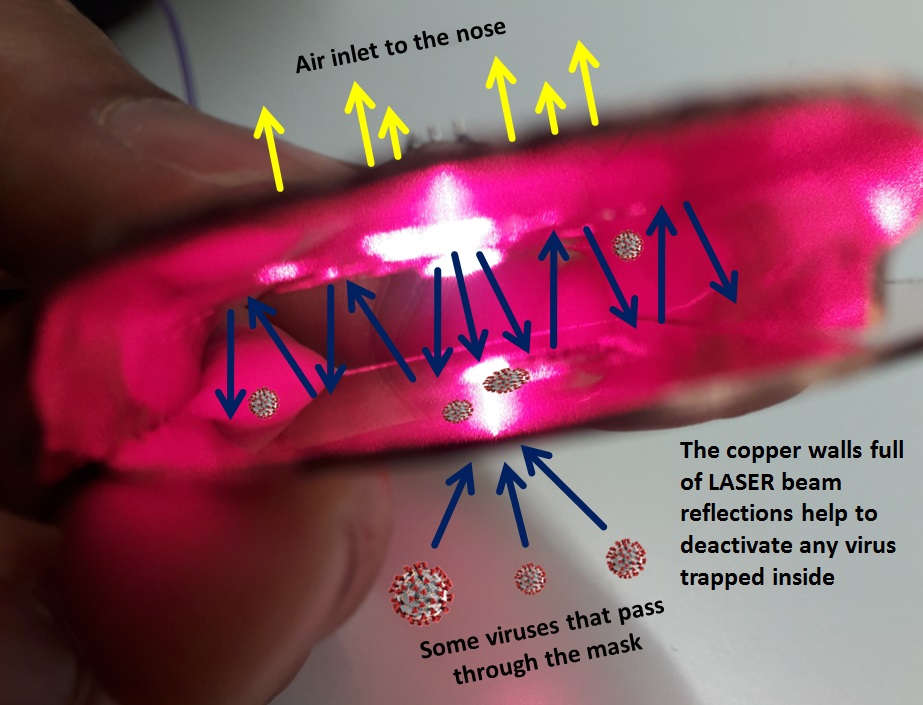

The air inlet/outlet shall be covered with a piece of clothes to keep the micro droplets attacked by the LASERs beam

Most of the people don’t used medical mask in their daily life, the LASER beams help to deactivate the virus

Vancouver Island Indigenous artist Howard La Fortune

Application in real life situation

Fying has never been safer during COVID-19

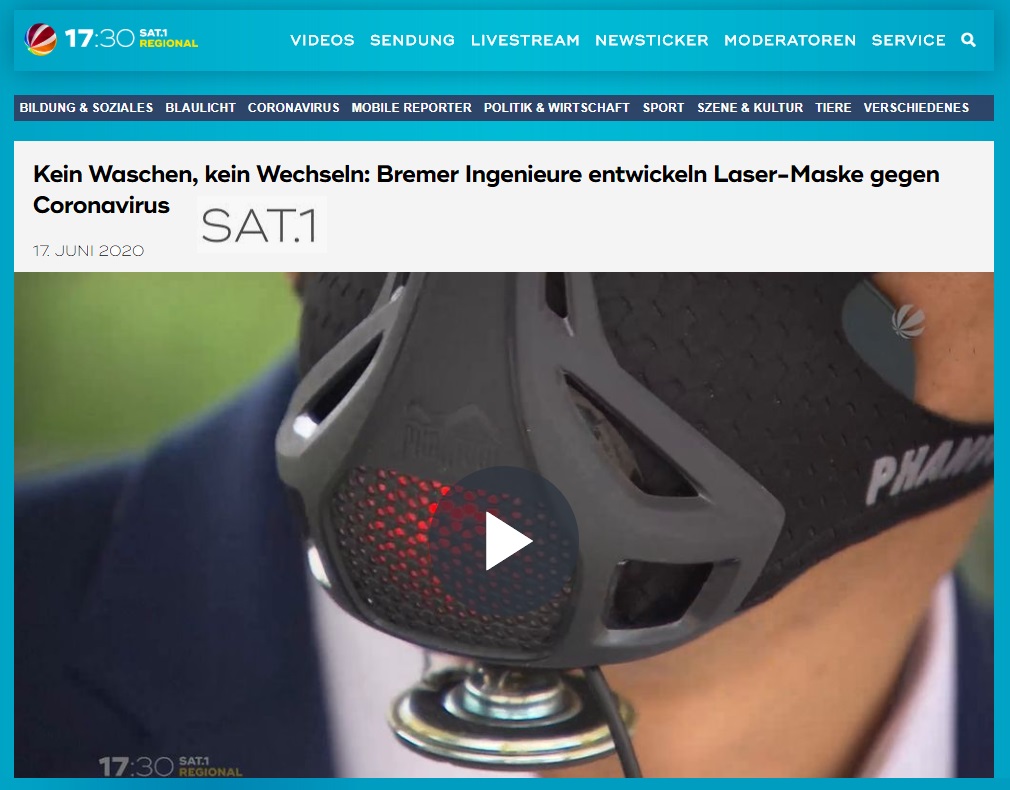

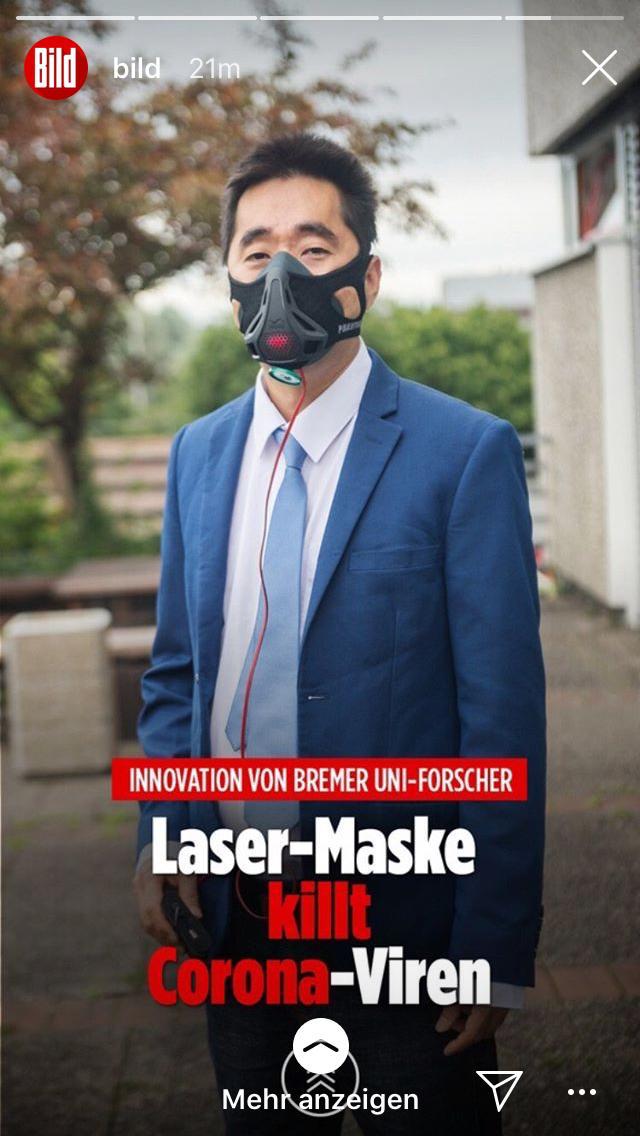

The articles about the mask have been published on:

This Magazine also interviewed great people as:

Dr. Michio Kaku:https://en.wikipedia.org/wiki/Michio_Kaku

Dr. Ronald Mallett:https://en.wikipedia.org/wiki/Ronald_Mallett

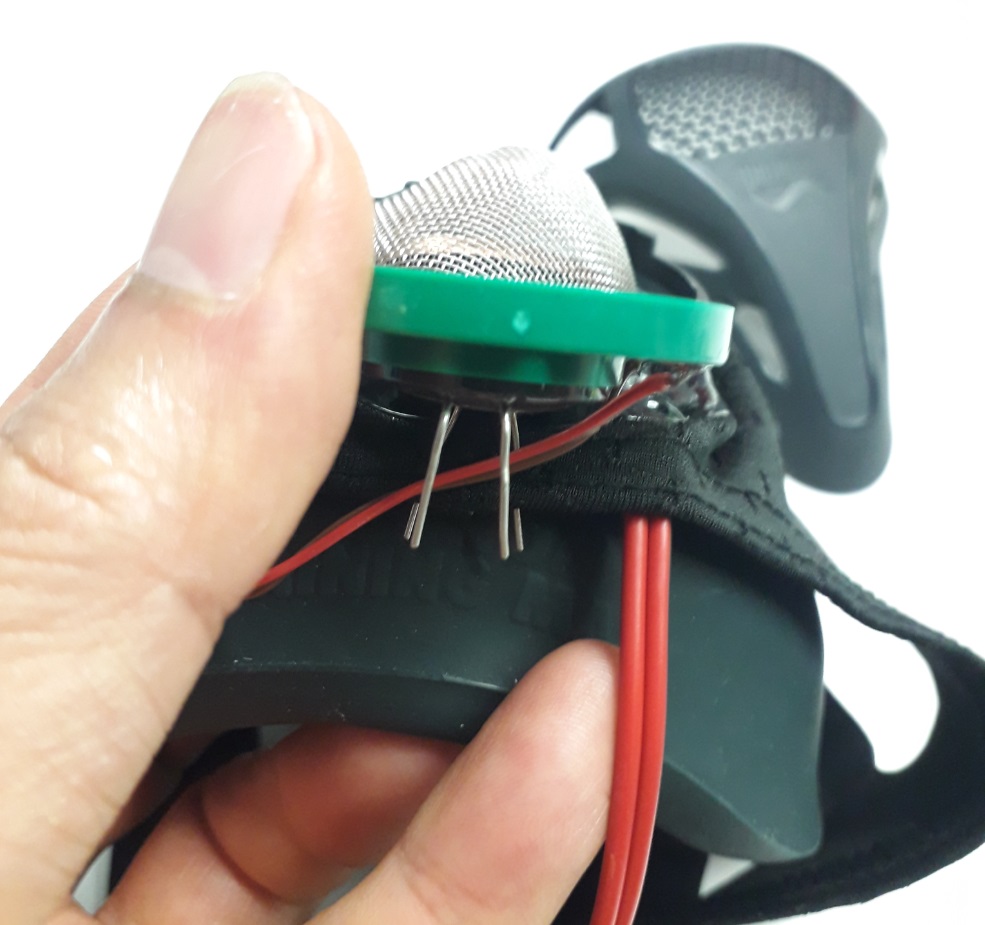

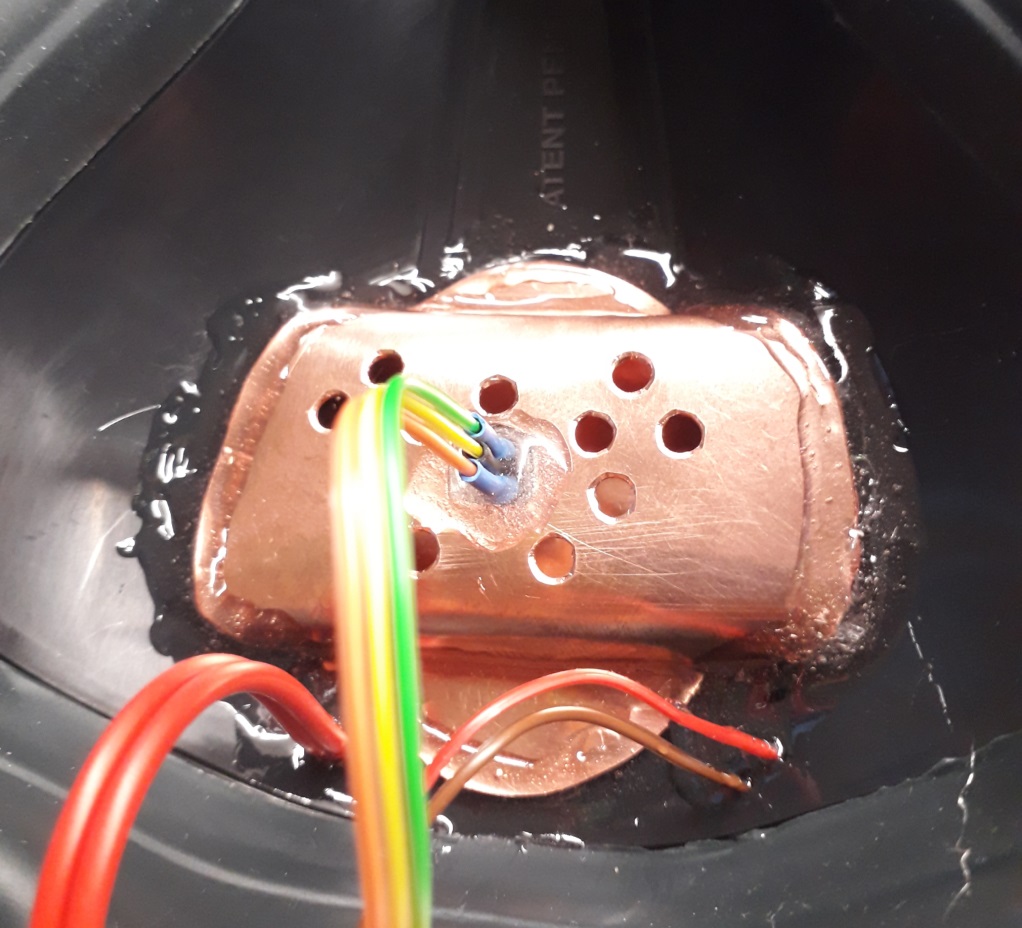

Bend the wires and solder the wires together

This shall be the final result and wish you a good luck !!!

This is the money you shall spend to used one of the following training masks to build your own COVID-19 LASER/Chopper mask

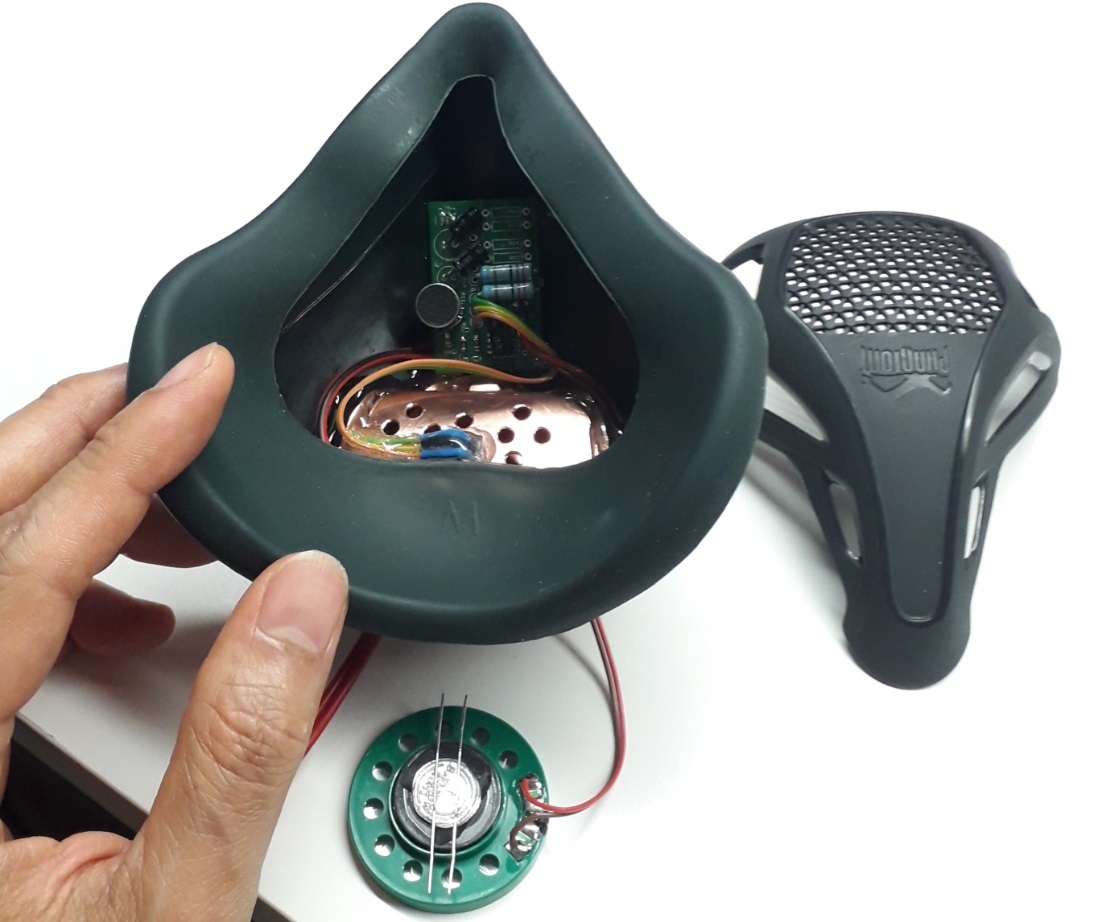

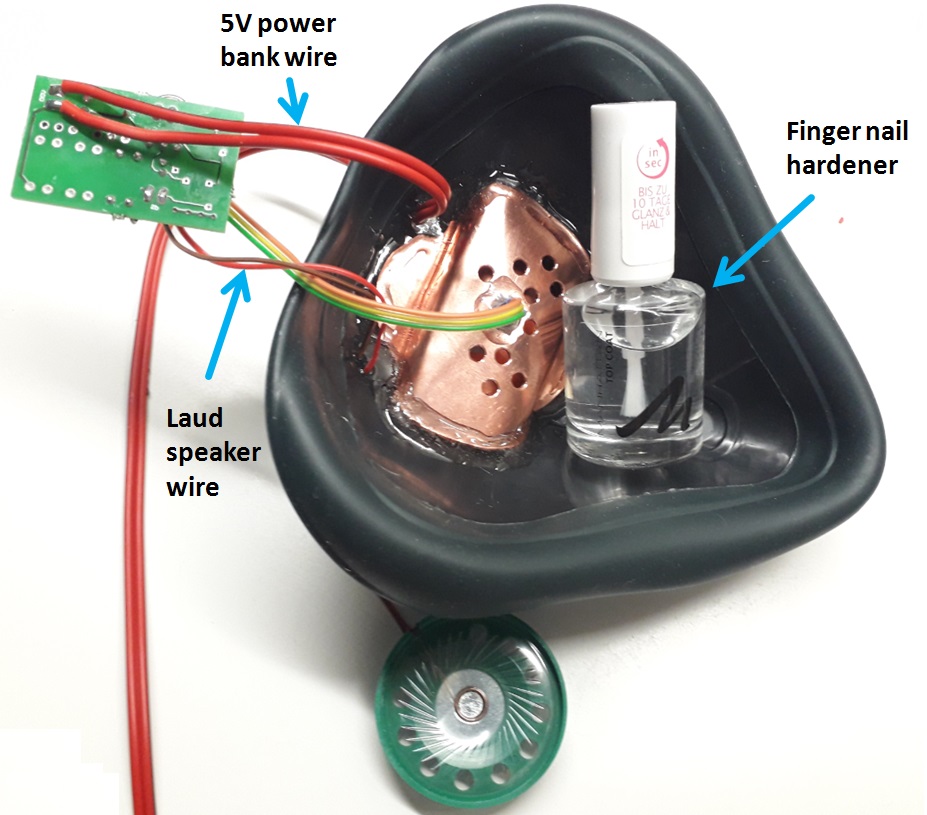

All part of the electronics are coated except the microphone

Attach the wires behind the laud speaker to the bottom edge of the cloth

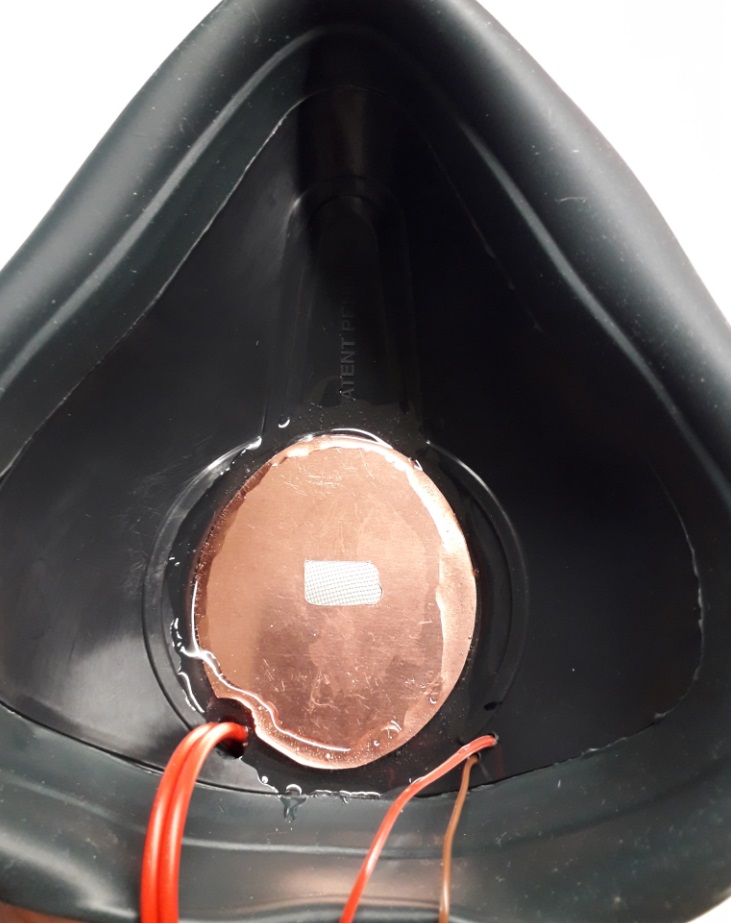

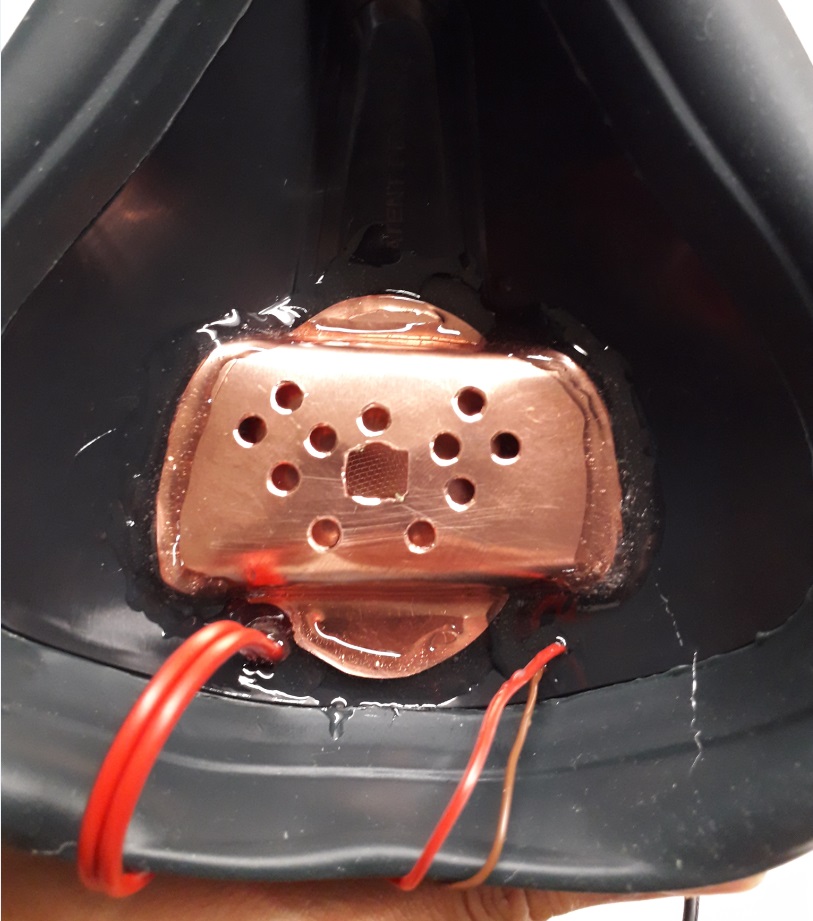

Epoxy adhesive is used to seal the air from outside

The LASER Diodes shall be fixed with epoxy adhesive

A simple solution with finger nail hardener is enough to protect the electronics from the moisture while we breath and talk inside the mask.

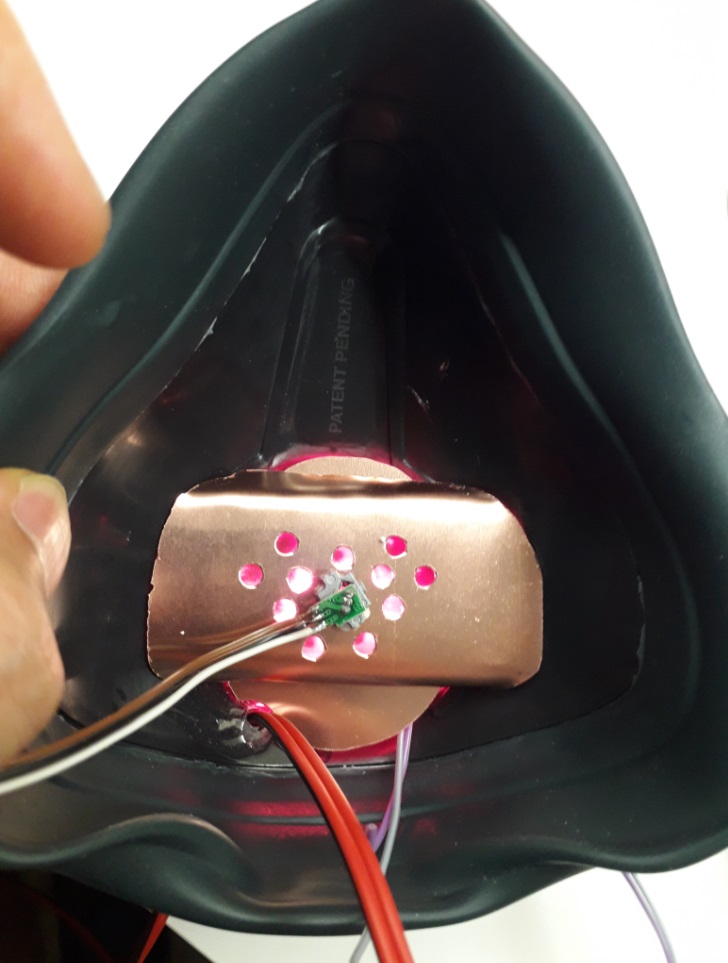

Adjust the LASER diodes for optimize focus and reflection.

This is how the LASER beam spreading to the stainless steel filter

The LASER beam attacking the cloth/medical mask

Align the LASER beam to fit the inlet/outlet hole

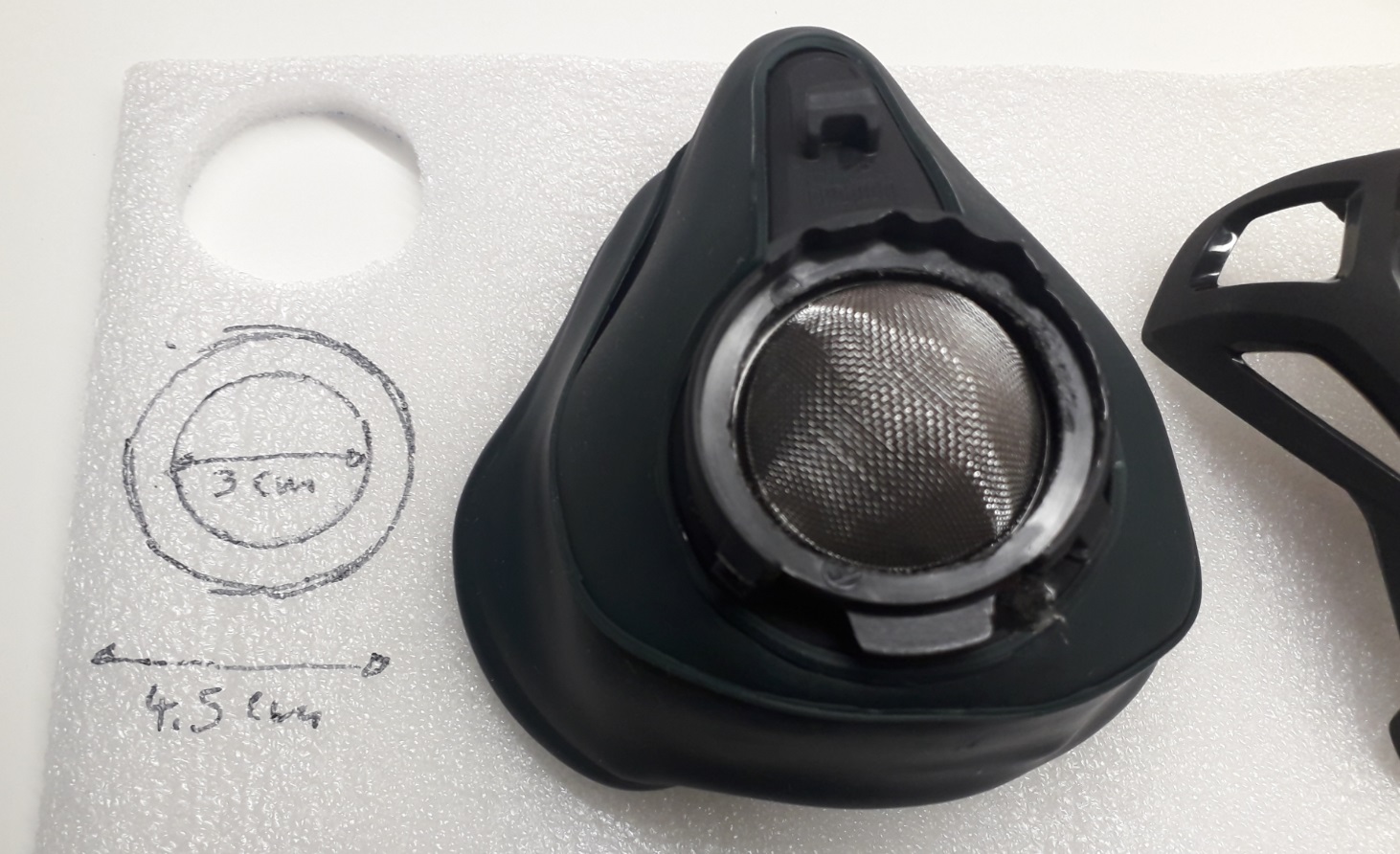

Cut the inlet hole to fit the stainless steel filter to hold the cloth/medical mask

The stainless steel filter from 1€ shop

Fit the stainless steel filter to the mask and cut a peace of sponge for holding the cloth/medical mask

Glue the stainless steel mask with epoxy adhesive to the training mask

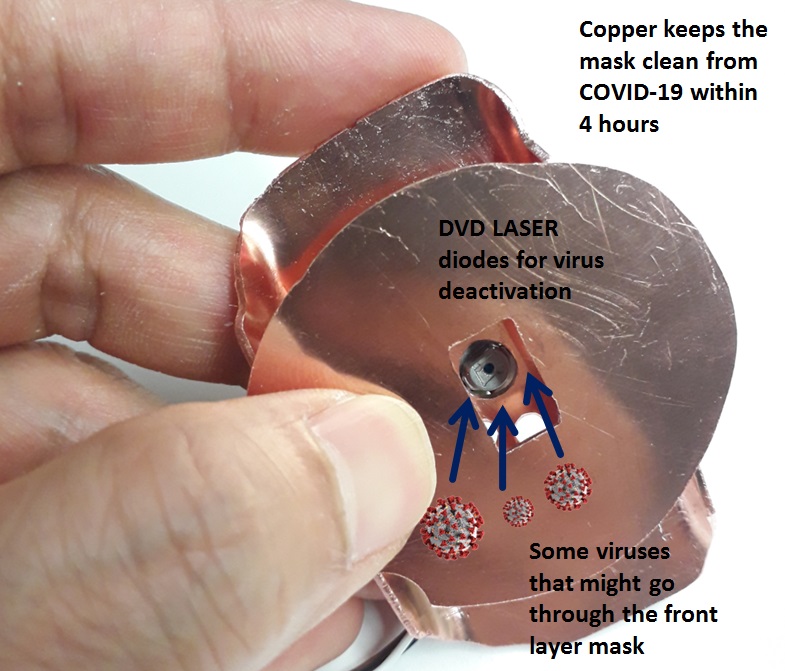

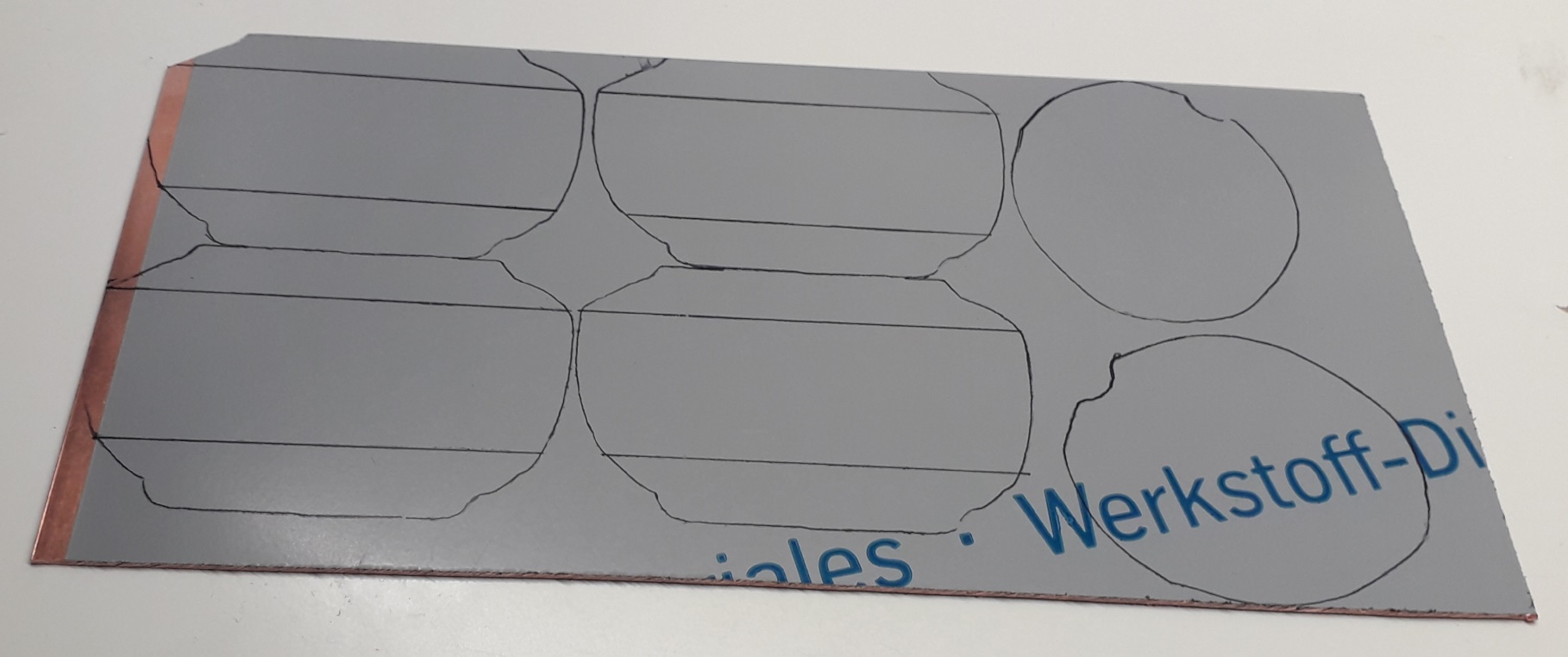

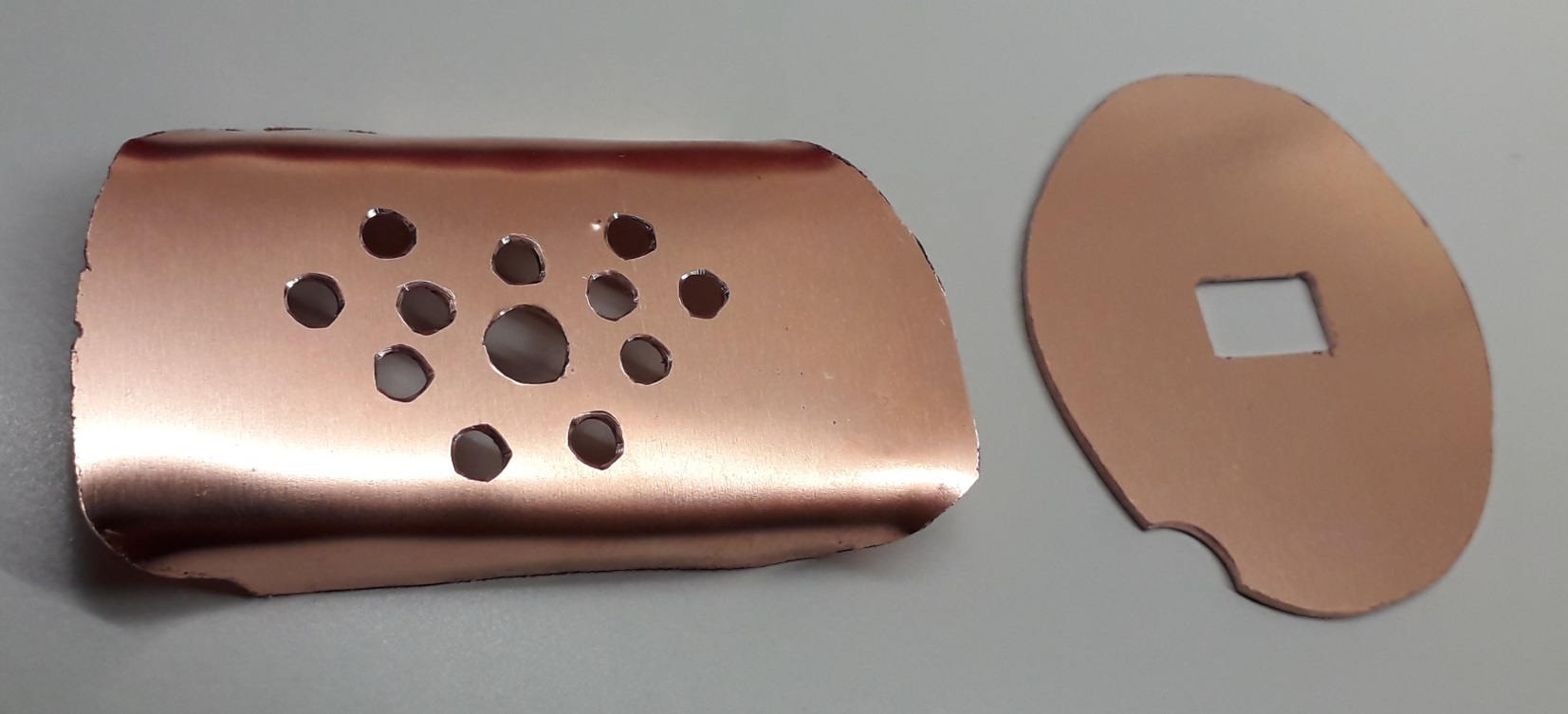

A 99% copper sheet is required to optimize its antimicrobial protection. The following is to create a cooper trap for the viruses and reflects the LASER beams inside for more virus deactivation effectiveness.

Press the sponge to hold the cloth/medical mask

Version 2.0 LASER Mask with Chopper filter trap

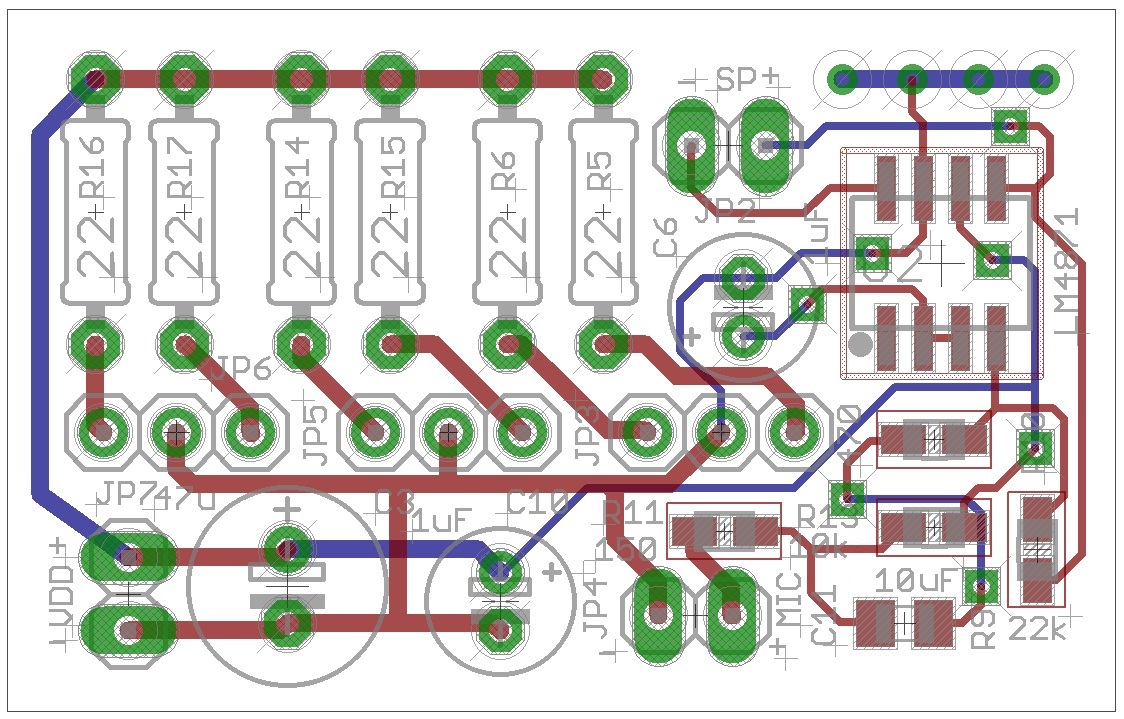

EAGLE PCB

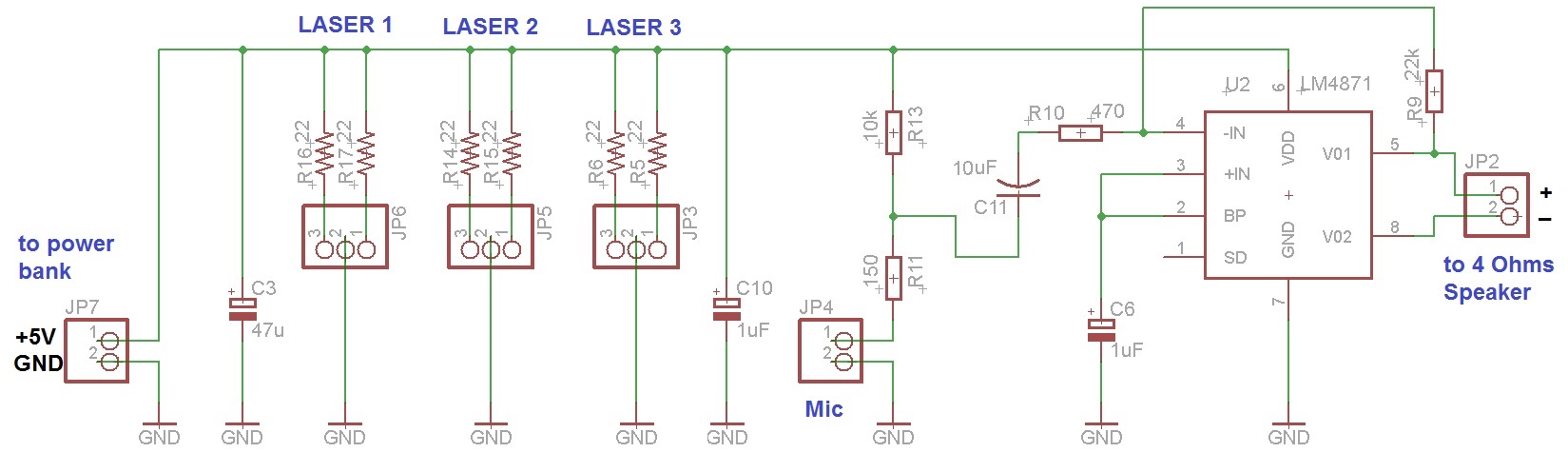

EAGLE Schematic

Follow this tutorial to build COVID-19 LASER/COPPER mask

The results showed that 96% of the virus was killed off in two hours and 99.2% in 5 hours, compared to no change on stainless steel surfaces over the same period, Kennedy said. This is in line with a U.S.-government funded study bit.ly/2WdhxZR published in March that found SARS-CoV-2 remained viable for up to 4 hours on copper, compared with 2 to 3 days on plastic and stainless steel.

https://www.reuters.com/article/us-health-coronavirus-copper-antimicrobi/copper-takes-aim-at-covid-19-with-virus-killer-coatings-idUSKBN22K0RX

If you want to have a microphone and laud speaker on the mask, you may use the circuit and PCB below (this is optional and only for the people who know about how to build their own electronic circuit)

https://www.insider.com/does-copper-kill-germs-and-viruses

Prepare any training mask as shown below.

Version 1.0 LASER Mask Tutorial

This is the money you shall spend to used one of the following training masks to build your own COVID-19 LASER mask

- Light as a potential treatment for pandemic coronavirus infections: A perspective