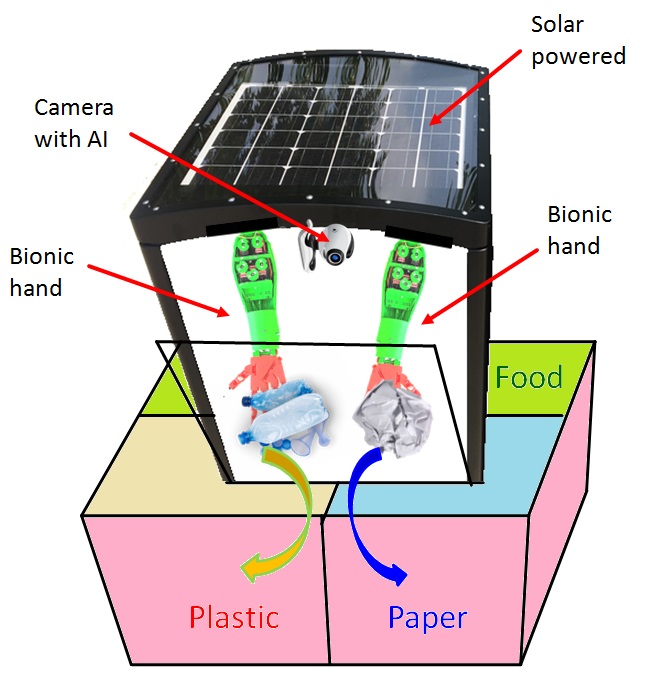

The tutorial to build your own robotik and arficial intelligence solar powered waste sorting station !!!

This is an open source concept and anyone is welcome to try!!!

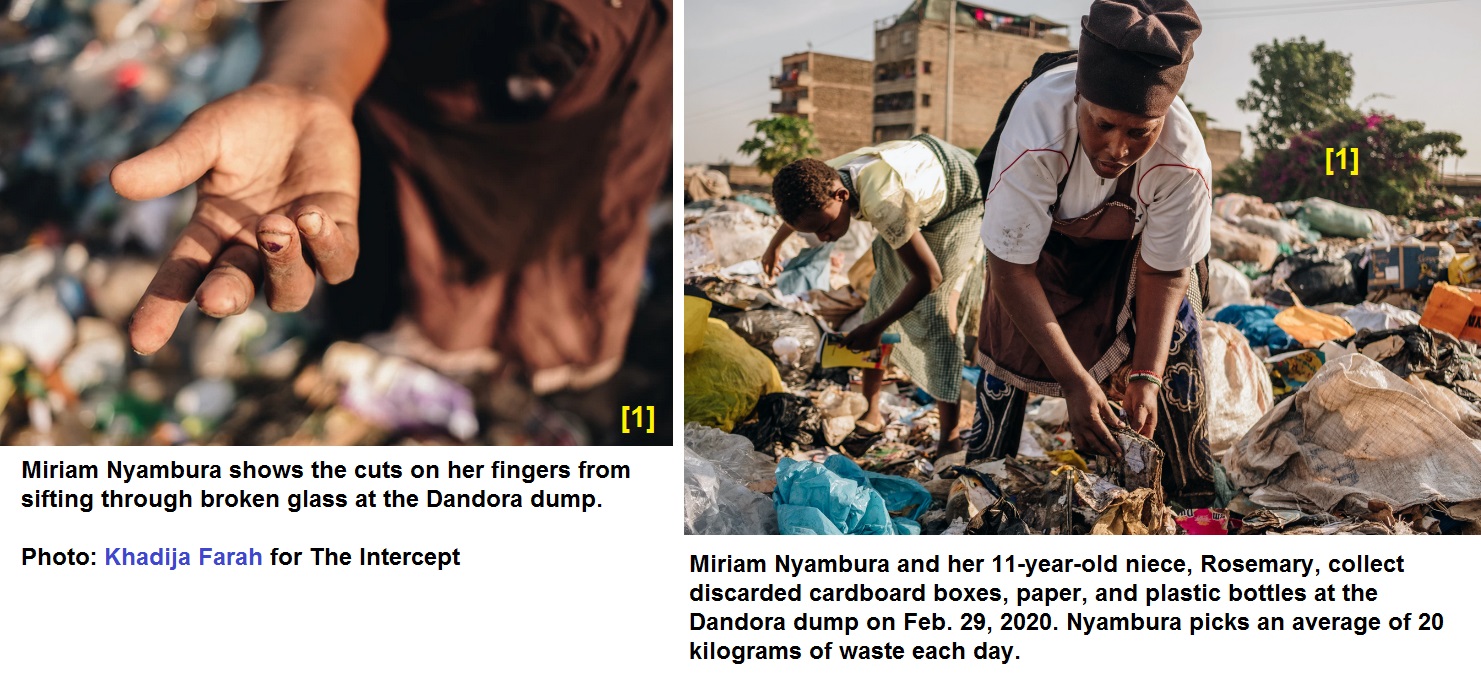

I am Ahmed Mekky, I am currently studying in master program at the University of Bremen in field Control, Microsystem and Microelectronics. During the corona crisis I am very concern with human direct contact on waste recycling processes by sorting waste with bare hand such as plastic, paper. This activities is very dangerous for poor people living by sorting trash.

[1] https://theintercept.com/2020/04/19/africa-plastic-waste-kenya-ethiopia/

If you want to know more or join me in this start-up project, you may contact me on:

ahmed.hassan.mekky@gmail.com

Mobile number: +49 176 74 78 94 46

Whatapp number +20 1002 78 58 63

I came out of the idea to realized the automatic sorting process with a robotic arm by recognizing the objects with artificial intelligent algorithm, with the help of Bremen Dynamics and the University of Bremen, get motivate me to do startup by developing and making a tutorial of the robotic arm to allow everybody in the world to try themseves in their own countries.

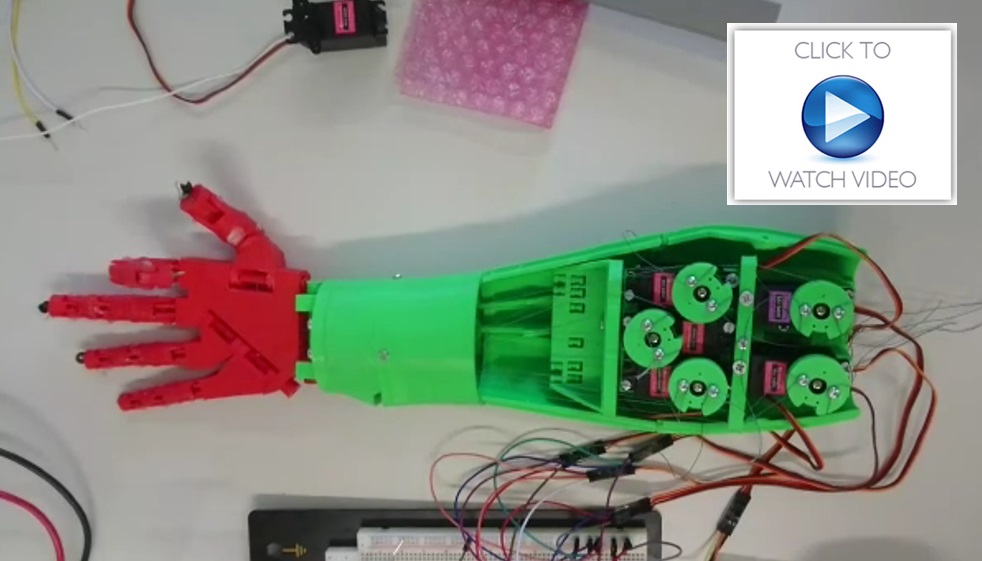

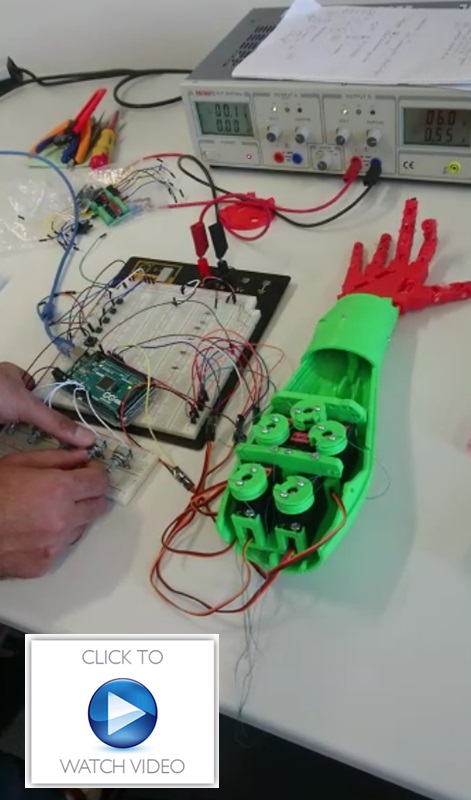

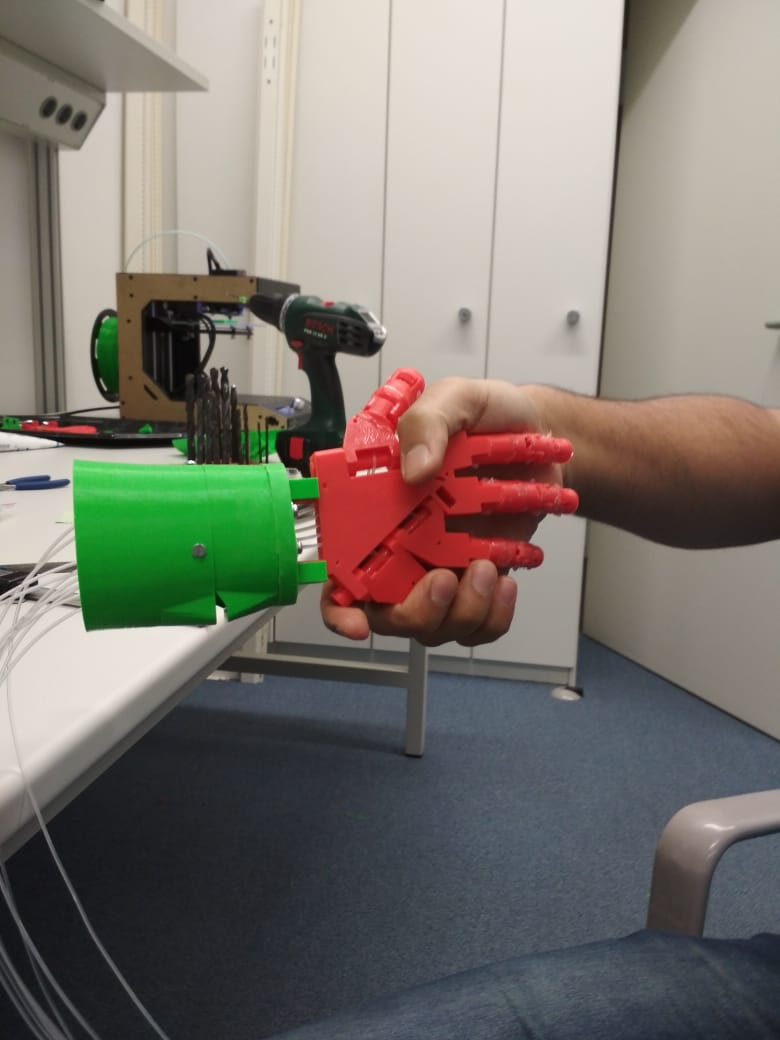

The bionic finger in action !!!

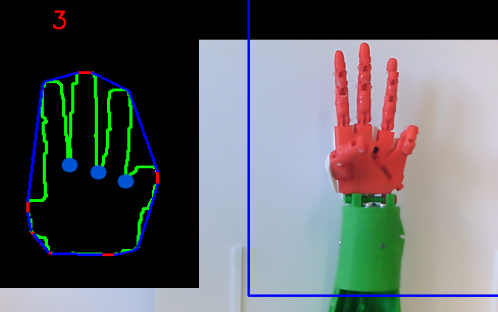

Testing the artificial intelligence to recognize number !!!

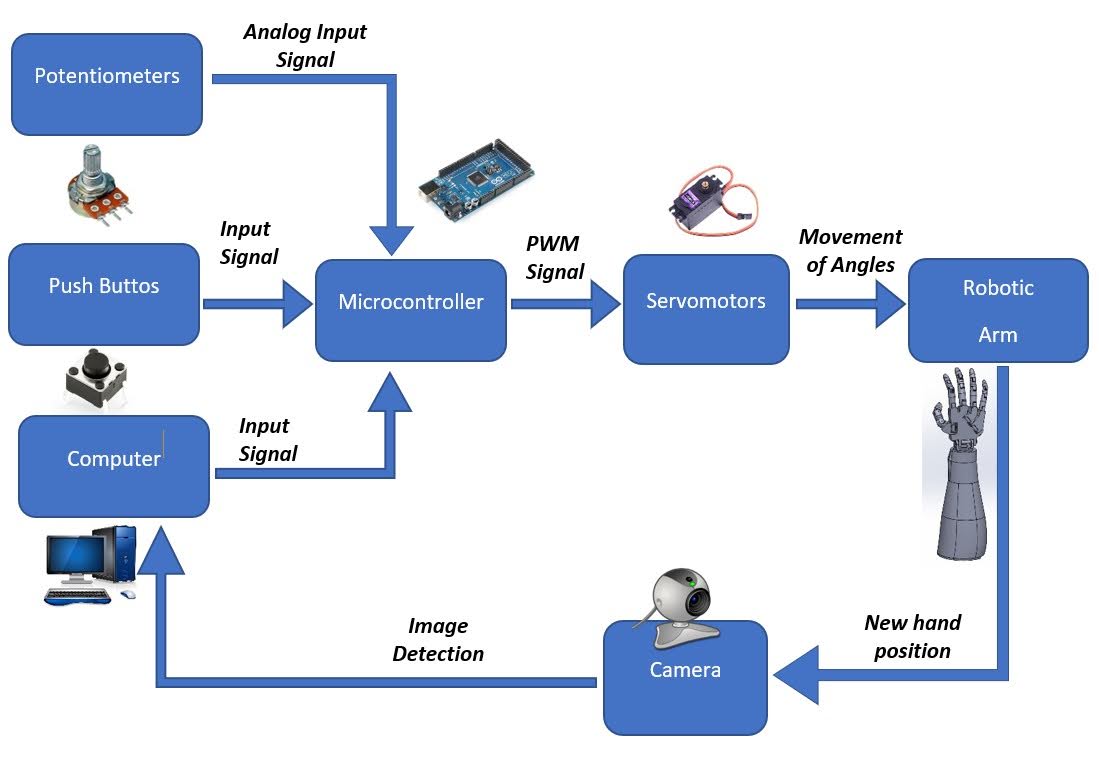

The block diagram to controll the finger and hand !!!

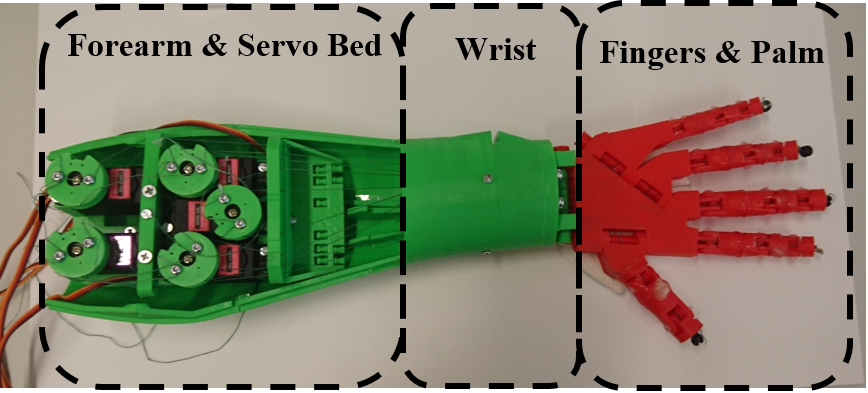

Building the bionic hand and finger step by step !!!

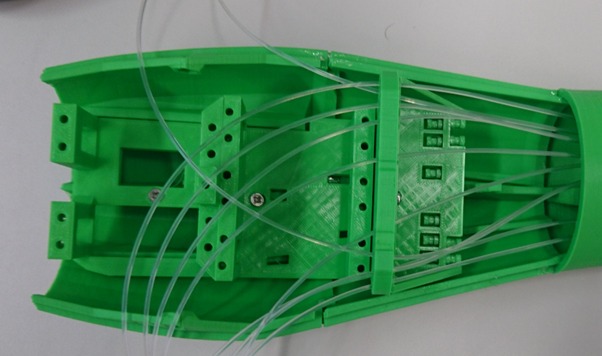

Prepare the equipments as shown above

The 3D printer files of the mechanical part can be downloaded from the following open source project for free:

This is the German 3D printer from Conrad we have in the lab

It takes time to smooth the delicate parts

Now it’s time to deal with the mechatronic parts !!!

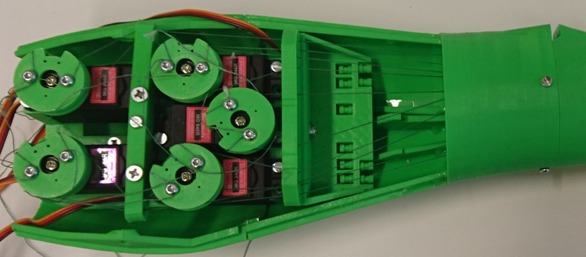

Forearm parts after the assembly of the servomotors and pulleys

Assembly of the hand Support base and Forearm

Assembly of the servomotors and Pulleys

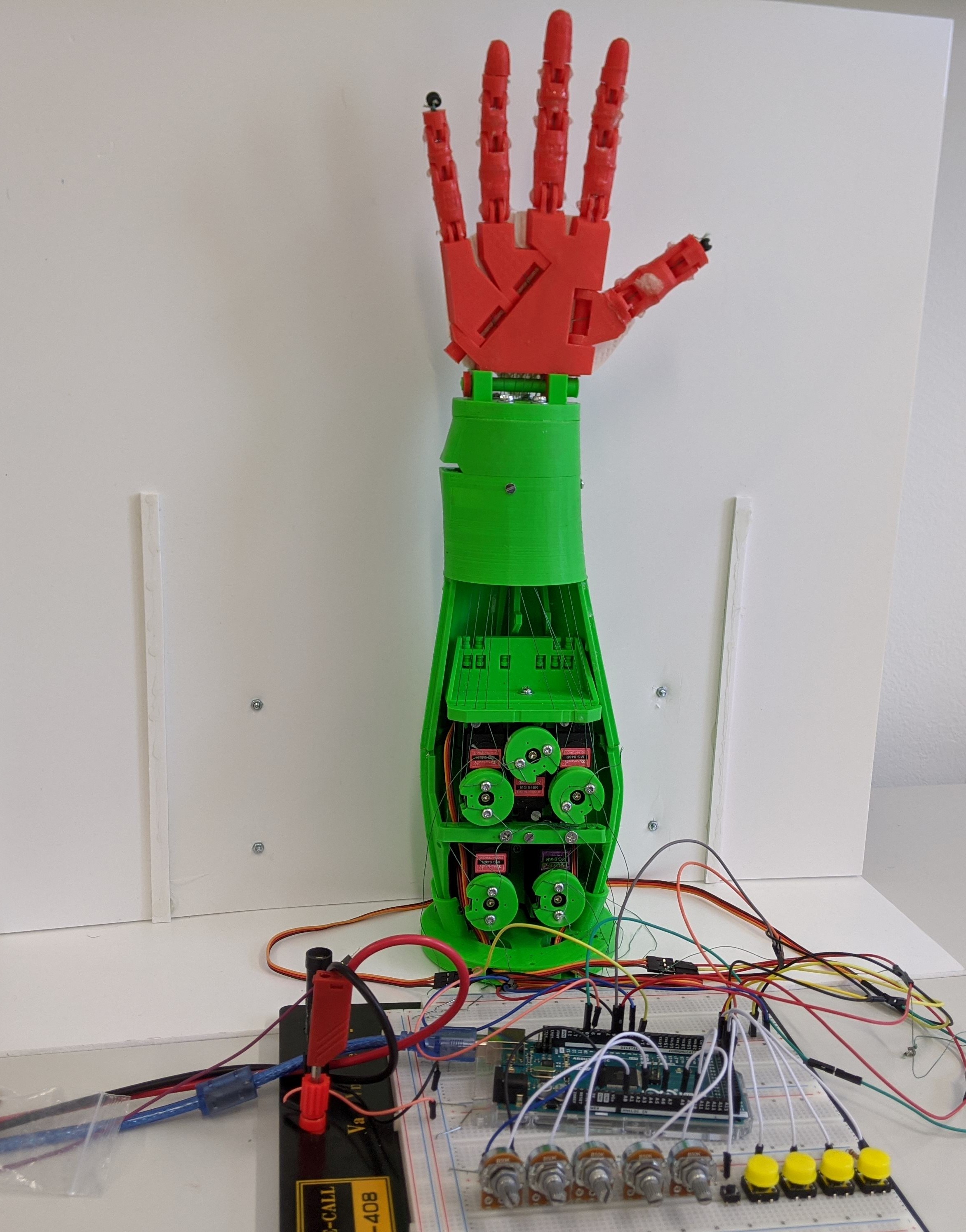

first attempt of complete system assembly

Frist check hand

Some personal reflection about Bremen Dynamics !!!

I came to know about the Bremen Dynamic from my researcher lab in ITEM (Institut für Theoretische Elektrotechnik und Mikroelektronik) at University of Bremen. There is a collaboration between my lab and the Bremen Dynamic (this is a non profitable organization consists of industrial people and academician to motivate students to do start up during and after their study).

In general, robots can access difficult places that can be dangerous to humans. The robots can do tasks with consistent quality in any condition (hot/cold weather). It can be used in several applications. For example, industrial and medical applications (Artificial parts), picking the fruit during harvest time.

In my lab, I got the technological support from Prof. Dr. -Ing. A. Garcia-Ortiz, and his Ph.D. students: Amir Najafi and Ardalan Najafi. ITEM provides us with working space and some tools. Bremen Dynamics links industrial need with the start up idea in order to prepare the prototype up to industrial standard when I make it as a product.

Bremen Dynamics allow me to do brain storming during the design and prototyping for optimal outcome of the prototype. This increases the chance to be successful when I start my own company after the study.